Introduction to PNR Italia

Established in 1968, PNR Italia is a proud part of the Tecomec Group since 2024, with decades of experience in designing and producing high-quality spray nozzles and systems for large industrial plants. Renowned for its Italian-made technology and innovation, PNR Italia has been a trusted partner across industries worldwide.

Adoption of CFD at PNR Italia

Committed to continuous improvement, PNR Italia has invested in a dedicated Computational Fluid Dynamics (CFD) department over recent years. CFD serves as a vital tool to enhance product performance, providing deeper insights into spray and atomization processes to fine-tune nozzle design and operational parameters.

Air-Mist Spray Technology – Overview of Twin fluid mixing sprayers

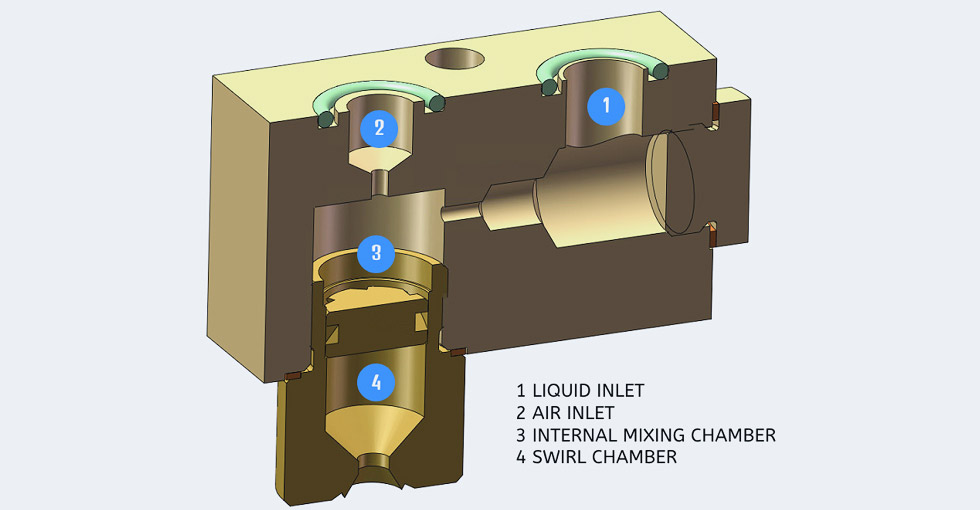

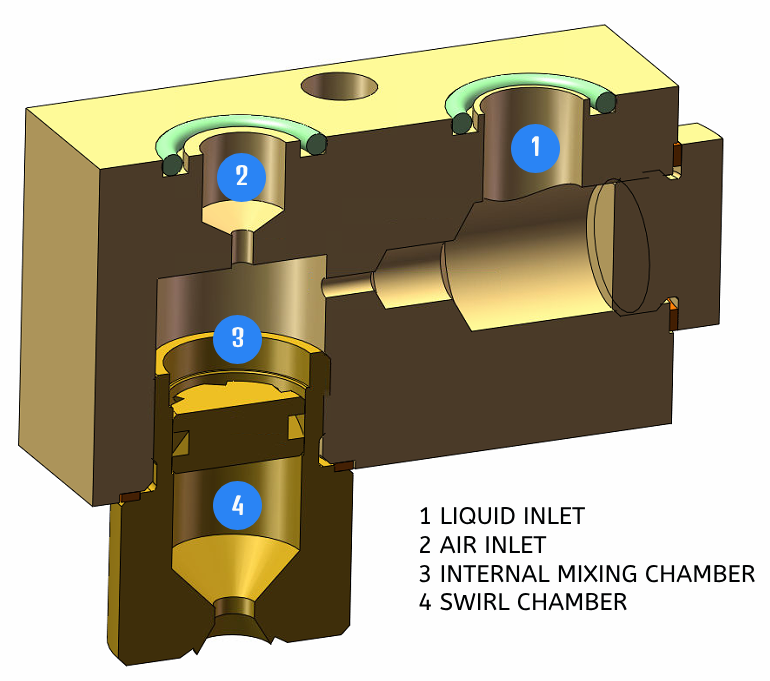

Below is a detailed diagram of the Twin fluid mixing sprayer. Pressurized liquid (1) and gas streams (2) interact together in the internal passages of the device. The mixing chamber (3) provides a first liquid jet break-up by means of the intercepting air jet. The nozzle tip, usually arranged with a swirler (4), provides a desired spray geometry.

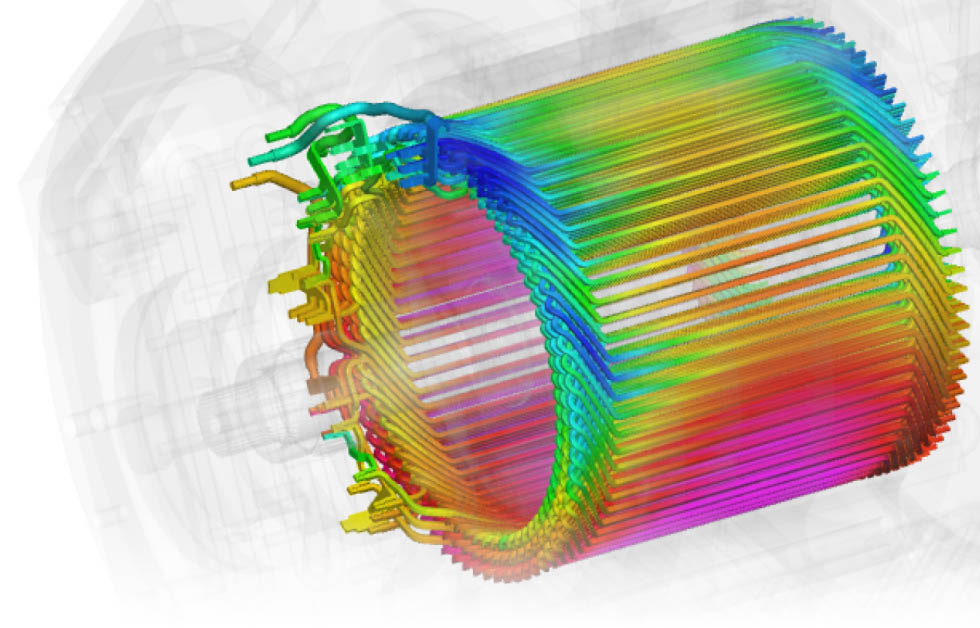

Below is an Isosurface image from the Air Mist Spray CFD simulation. The internal fluid-dynamics involved are unique and very complex. Liquid and gas jets collide in crossflow and the Volume-Of-Fluid (VOF) model used in the simulation must be reliable.

Fluid – Wall interaction is also critical in the Internal Mixing Chamber (3). The twin-phase mixture flowing into the swirler’s passages receives a turbulent motion. Within the swirling chamber the liquid is forced to adhere to the walls (centrifugal effect), the air remains in the cyclone’s eye and is accelerated through the final orifice.

Challenges in Spray Cooling for Steel-Making

In the steel-making industry, precisely controlling the cooling rate of hot steel surfaces is critical. PNR Italia faced the challenge of accurately predicting the Heat Transfer Coefficient (HTC) of its air-mist nozzles under varying conditions such as feeding pressures, steel temperatures, and air/water consumption. Key difficulties included understanding complex breakup fluid dynamics and developing thermal models to optimize nozzle performance within a cooling tunnel environment.

How Simerics Addressed the Challenge

Using Simerics’ CFD software, PNR Italia developed and validated computational models to predict HTC curves with remarkable accuracy, especially in cooling regimes under the Leidenfrost limit where boiling effects are minimal. The Volume of Fluid (VOF) module efficiently managed the nozzle’s internal multi-phase mixing and external spray break-up with limited computational resources, making simulations economically viable for industrial use.

Conclusion

Both air and water flow rates were close to the measured values for the same working condition (error within 3%). The measured droplet velocities from PNR’s laser interferometry apparatus found correct feedback from the CFD model too.

PNR Italia’s synergy with customers and usage of advanced CFD (Simerics) have proven invaluable in optimizing spray cooling in steel-making processes.

This approach not only enhances nozzle tuning for desired cooling speeds but also sets a benchmark for industrial-standard simulation and quality.